Twin-screw extruder (screw and barrel) by extrusion system, the transmission structure (reducer, bearing and motor), feeding system, heating and cooling structure and control system of five parts, with single screw extruder, twin screw extruder barrel, two root screw, charging part adopts spiral forced feeding within the barrel, screw with bearing specifications and layout is more complex.

A, extrusion system

1, the structure of the screw

Is a major part of the extruder, twin screw of the double screw screw tooth does not conform to the rules, cannot form a closed meshing line, belongs to the sealed type. Screw locking, rely on gear transmission, master-slave screw does not directly contact

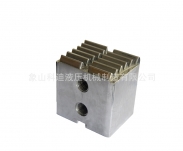

2, the structure of the barrel

A metal tube, heat resistant, wear-resisting, corrosion resistance and other properties. Barrel and screw, implementation of plastic pieces. Twin-screw extruder barrel structure and 65 single screw extruder barrel structure form, also of monolithic machine barrel and sublevel combined barrel. In twin screw extruder, the meshing differential rotating twin screw and conical twin-screw extruder is generally adopt and barrel; One of the few large extruder using segmented composite barrel, for the convenience of mechanical processing.

Second, the transmission structure

The function of transmission system is driven screw, supply the screw in the required torque and rotational speed in the process, usually composed of motor, reducer and bearing.

Double screw in the work when the axial force and work in single screw extrusion when the axial force is similar to or higher than that of single screw extruder of axial force, such a large axial force should need large size bearing to bear, but, as a result of the double screw work arrangement limits the screw under axial force in the bearing arrangement space, and thus how much bearing arrangement scheme.

Third, charging system

According to the characteristics of the twin-screw extruder extruded raw material and working condition requirements, the twin screw extruder system USES is force measuring way of feeding tube feeding for machine.

The feeding device as an independent work of single screw extruder, turn the conveying raw material of the screw by a dc motor through the worm worm gear reducer output shaft drive. Screw conveyor speed of raw materials, the size of the transport capacity is by twin screw extruder work double screw speed, barrel temperature, products of liquid pressure and products of decide together with shoes. Feeding device of the thread on the threaded rod, can be single or double, more general application is a single thread.

Four, heating and cooling structure

Heating and cooling is the basic conditions of extrusion machine work, general is given priority to with resistance heating machine tube method. Commonly used is cast aluminum wire heater structure. This heater is fill the resistance wire join with magnesium oxide insulating material of metal tube, then casting metal pipe to the aluminum alloy sleeve.

Five, the control system

Control the operation of the twin screw extruder and stop

淘宝旺旺

淘宝旺旺

msn

msn